Assembling parts with different physical properties

This car manufacturer was faced with a problem related to the complexity of the shapes of the two parts to be assembled. The objective was to use a process that was valid for both plastic/plastic and plastic/glass assembly, so bonding was the most logical solution to this need.

Implementation of a complete line meeting the automotive FMECA

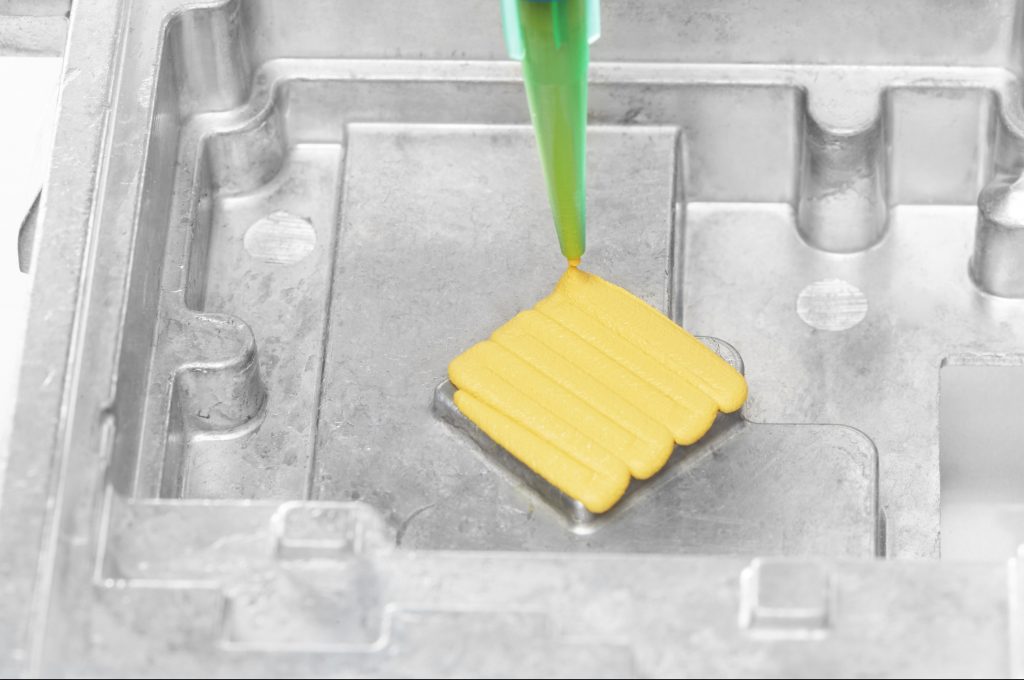

The technical teams developed a process: surface treatment with plasma, UV bonding with the use of an adhesive combining flexibility and productivity. This process provides the same function as ultrasonic welding and passes the thermal stress tests with flying colours. The implementation of this scenario has enabled the creation of a complete line via an integrator, responding to the FMEA method (Failure Mode, Effects and Criticality Analysis) in the automotive sector.