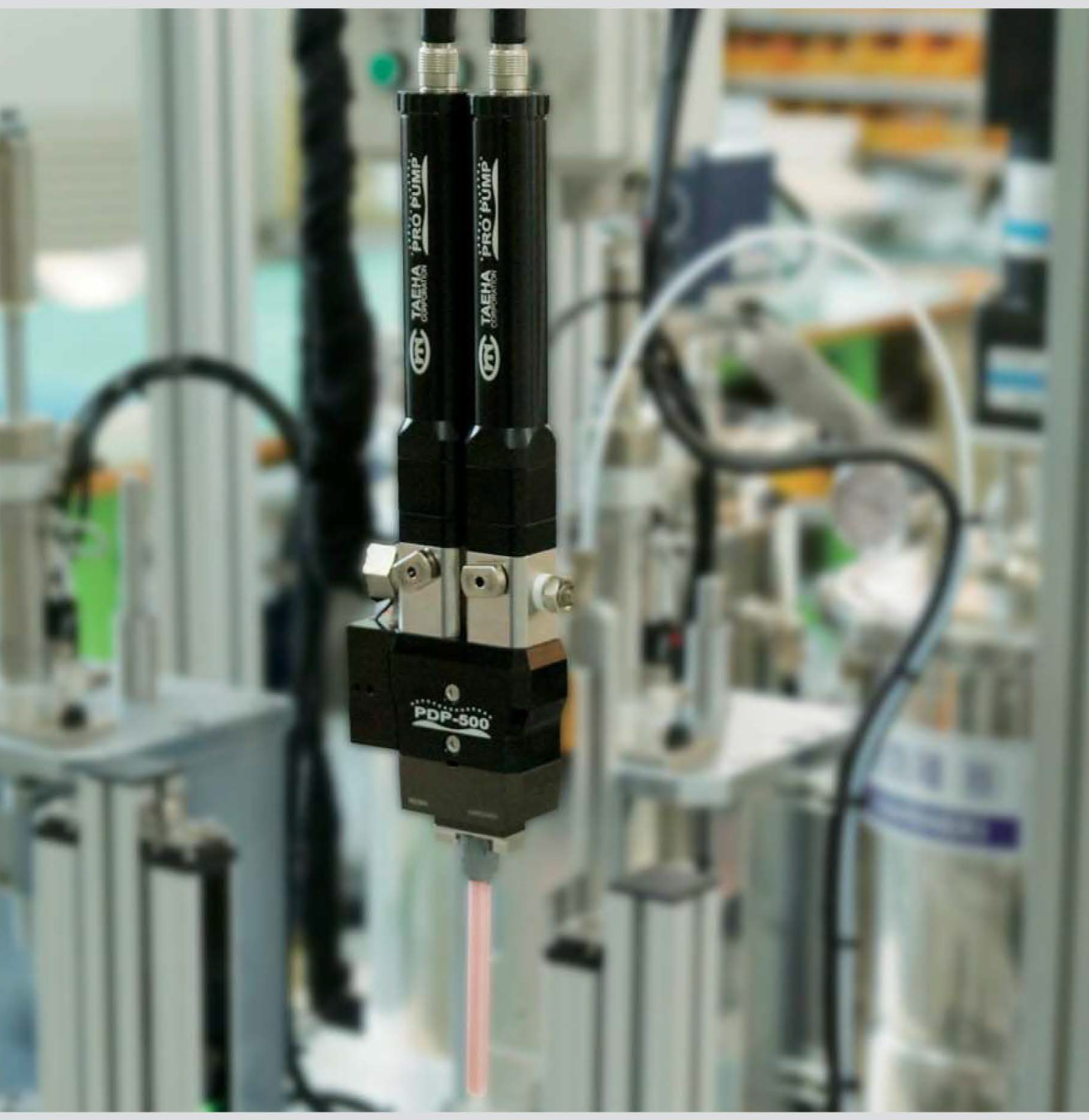

Dispensing volumetric pumps

2C Volumetric pumps

Precision dosing of two-component products with or without filler

The volumetric dispensing system is adapted to two-component products and allows the application of resins and adhesives while guaranteeing the respect of the mixing ratio and the volume to be applied. This dispensing is carried out at low pressure in order not to damage the material or sediment the fillers it may contain. The two-component volumetric dispenser guarantees a perfect mixture of the two products for ratios of 1/1 to 10/1. The range allows dosing between 0.01 ml /rev and 10 ml / rev.

There are different pump configurations depending on the component to be deposited:

- Standard (STD) for all conventional components,

- HFS for dispensing filled material.