Feeding systems

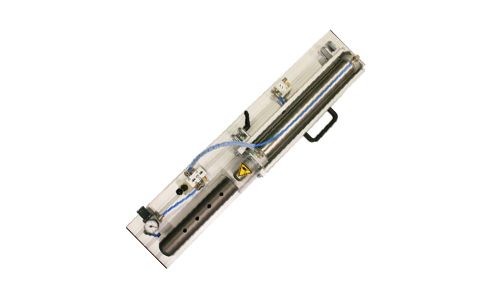

Cartridge Pusher with piston

Cartridge pushers are used for the transfer of materials packaged in 310 cc Euro-cartridge or Semco 600 cc and 900 cc cartridges.

The technology of the pusher cartridges varies according to the density of the material to be transferred.

Depending on your needs, there are standard or piston cartridge pushers for the transfer of very dense materials.