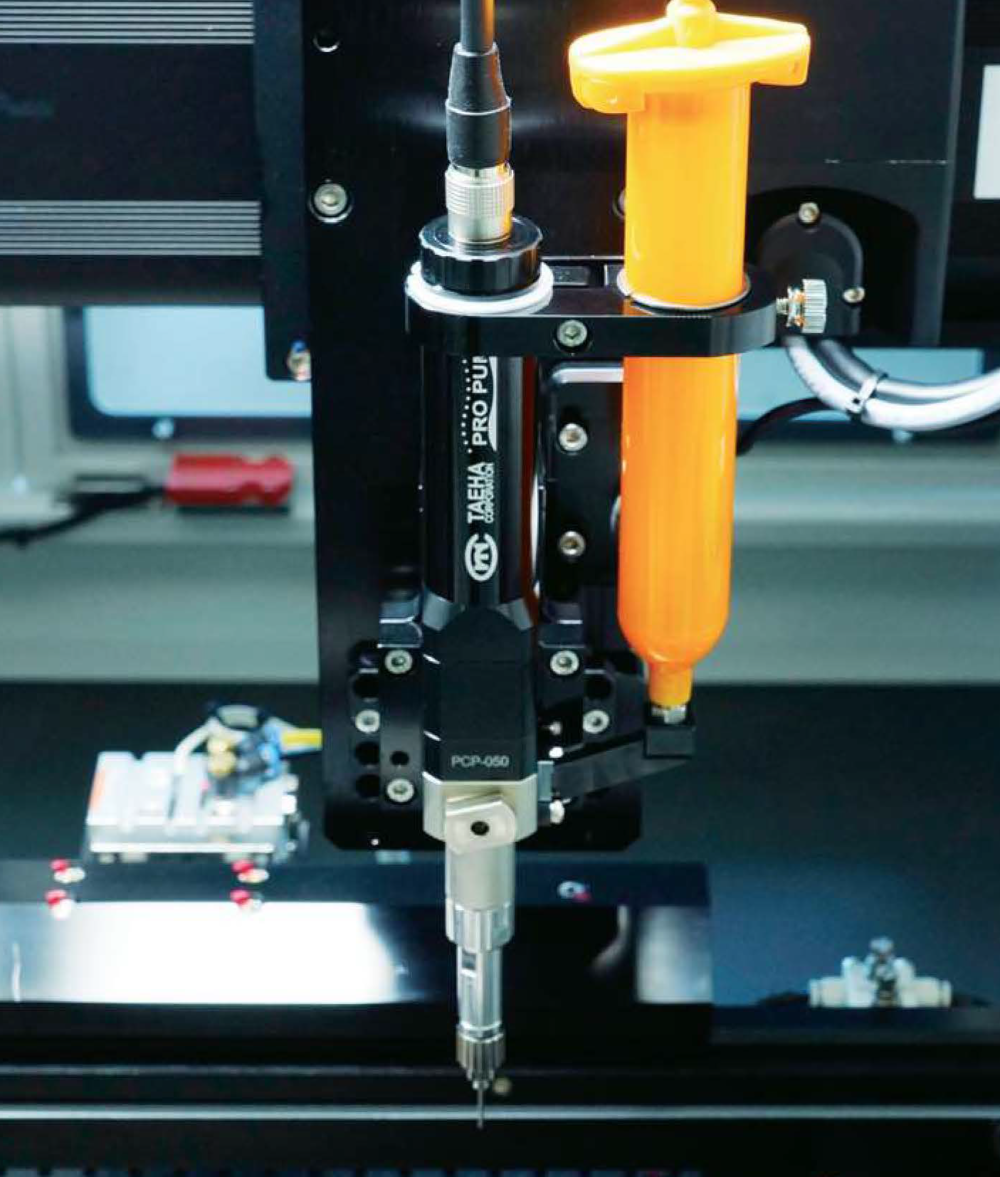

Dispensing volumetric pumps

1C Volumetric pumps

Volumetric pump, a versatile dosing system

Designed to dispense liquid or pasty products, it excels at dispensing abrasive materials, high viscosity, high solids, single or two-component bases, the high precision volumetric pump dispensing solution easily dispenses a wide range of products.

Regardless of the external environmental conditions (ambient temperature or temperature of the product to be dispensed), the precision of the volumetric pump dispensing remains unchanged and guarantees a very high reproducibility of the dispensing with ±1%. The range allows dosing between 0.005 ml /rev and 15 ml /rev.

There are different pump configurations depending on the component to be removed:

- Standard (STD) for any conventional component,

- HFS for dispensing filled material,

- PEEK for anaerobic glue application.