Surface preparation and treatment before bonding

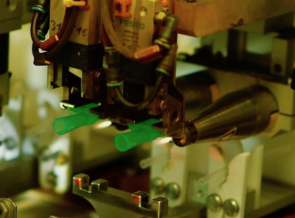

Plasma treatment

Plasma surface treatment allows the cleaning and preparation (by plasma activation) of materials such as plastics, glass, metal or textiles before printing, gluing or varnishing.

Metal Plastic Bonding