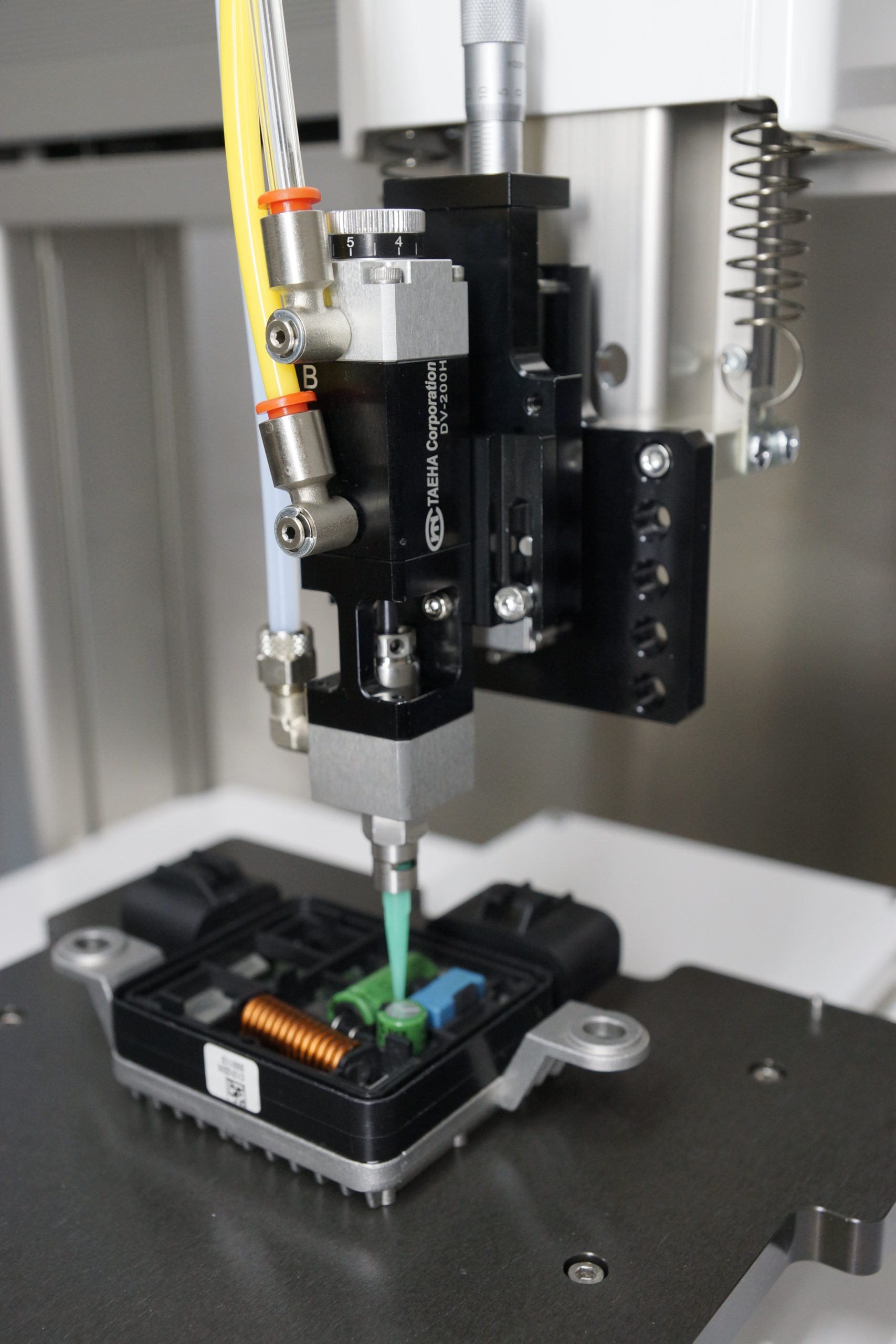

Dispensing systems

Dispensing valve

The metering valve is a reliable and accurate solution used in various industries for dispensing low and high viscosity, difficult to dispense liquids. The wide range of metering valves can be used for all types of dispensing and in different configurations. The metering valve is used for precise dispensing of liquids or pastes. Its ease of use and compact size allow for easy integration.