UV adhesives adapted to the transparency of glass

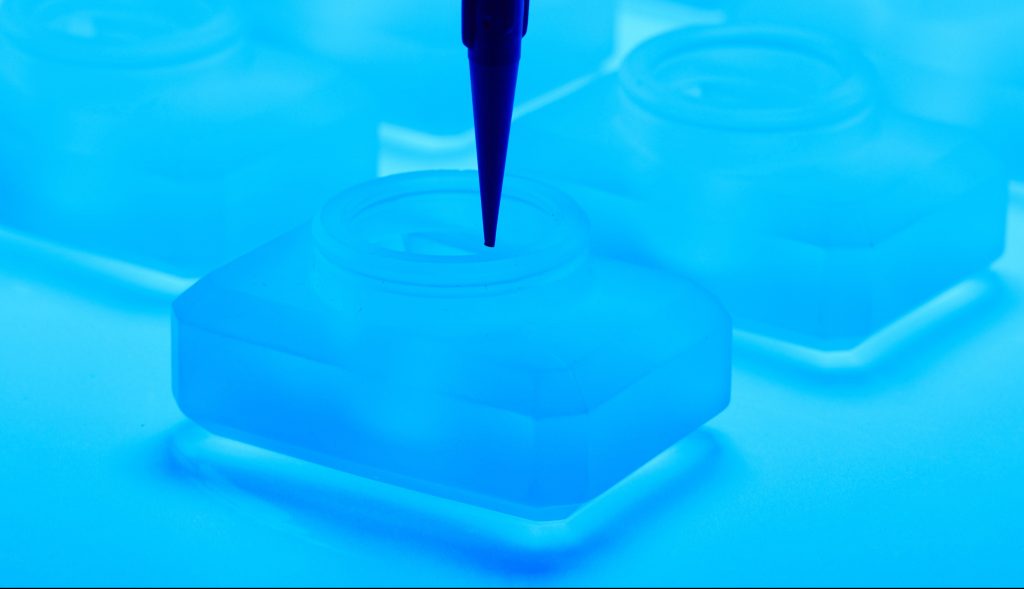

The most common process for joining glass to plastic is UV bonding. Fast, efficient and, above all, aesthetically pleasing, UV bonding will allow you to industrialise your bonding method to ensure increased productivity. UV bonding uses so-called photosensitive glue to join glass and plastic in a stable and durable way. UV adhesives guarantee a transparent bond thanks to their refractive index of 1.5, which is similar to that of glass.

Also classified as technical adhesives, some dual-curing adhesives (with two curing processes) are used in glass/plastic bonding processes. They polymerise in two stages, first with UV light and then with moisture, which makes it possible to neutralise any adhesive residues, particularly on cosmetic packaging.

See our technical adhesivesBonding, the ideal assembly method for plastics and glass

Although they have different physical properties, glass and pastic are the most relevant materials for bonding.

In the field of glass, the adhesive bonding technique allows glass to be joined with materials of different nature. The bonding of glass, like that of plastics, represents a special challenge in terms of adhesive properties, with very high mechanical strengths. These guarantee durable joints over time, and ensure watertightness and strength.

See our application cases