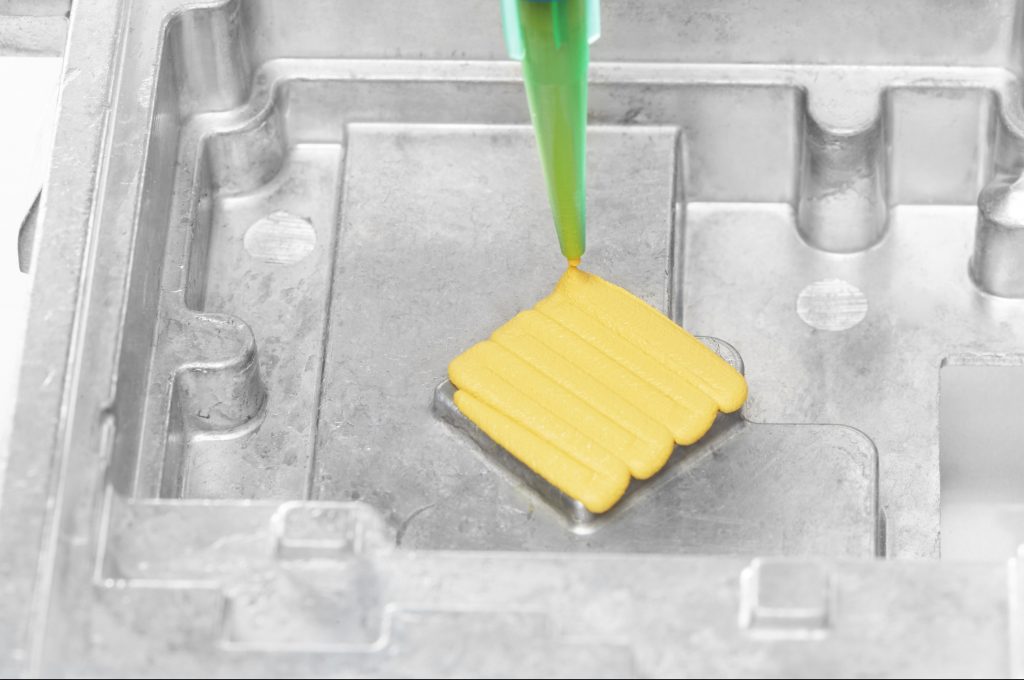

Gap filler dispensing

Thermal pastes such as Bergquist Gap Filler 1500 (GF1500) are highly filled products with an average density of 3 to 4. These thermal pastes are used to dissipate heat in electronic parts such as inverters for electric cars, a market that has been developing in recent years.

Syneo offers single and two-component dispensing systems, specially designed to deposit these charged thermal pastes with a rotor and a stator, special for the deposit of High Filler (HF) material. The accuracy of the systems +/1% and the repeatability 99% remain unchanged.

Recommendation of a volumetric solution

The SYNEO team guided the customer towards a volumetric HFS (High Filler System) dosing solution with the dimensioning of a volumetric drum emptying system for Bergquist GapFiller 1500 20L drums and a PDP-5000 HFS two-component volumetric dosing system which allows a maximum flow rate of 10 ml / rev.

The advantages of this solution are numerous, negligible loss of product in the drum, working at low pressure, no splashing when changing drums, reduced production downtime, precision and repeatability of dosing.