Protection of electrical connectors

A major car manufacturer has encountered a sealing problem with some of these connectors, particularly with its wiring harnesses. This problem is compounded by the position of the wiring harnesses, which are often subjected to the external environment, such as rain, mud, snow, salt, temperature, etc.

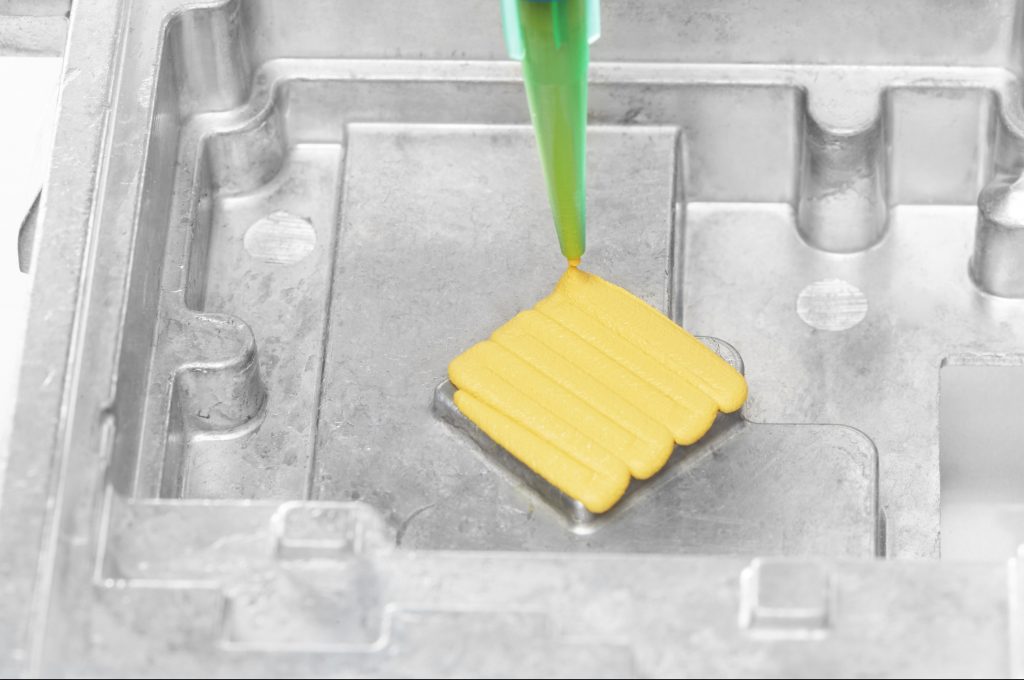

The objective here was to obtain a seal between the plastic and the 7-pin cables in order to increase the corrosion resistance and therefore the life of the connector.

Other automotive applicationSealing with silicone

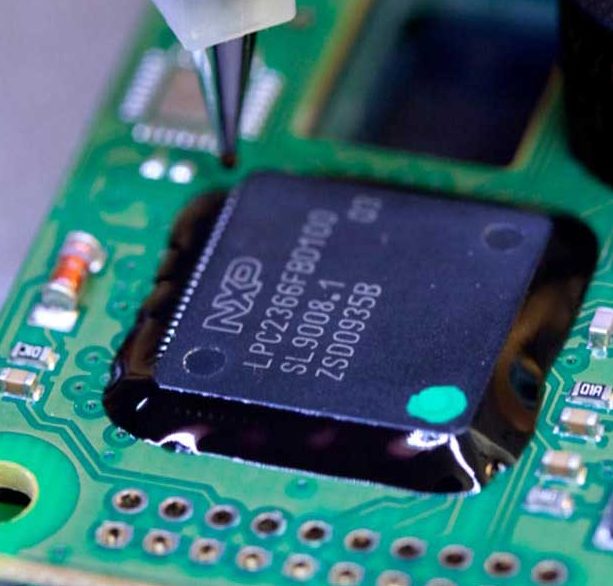

The solution proposed by the SUPRATEC Syneo teams was to apply a single-component, black, flexible and self-levelling silicone that holds well on plastic and electrical cables. The product selected is a non CMR product with a fast setting time of less than 10 minutes at room temperature.

This silicone has been used to protect connectors from the extreme external conditions to which tow bars are subjected, but can also be used for other connectors, such as vehicle lights.

Our silicones