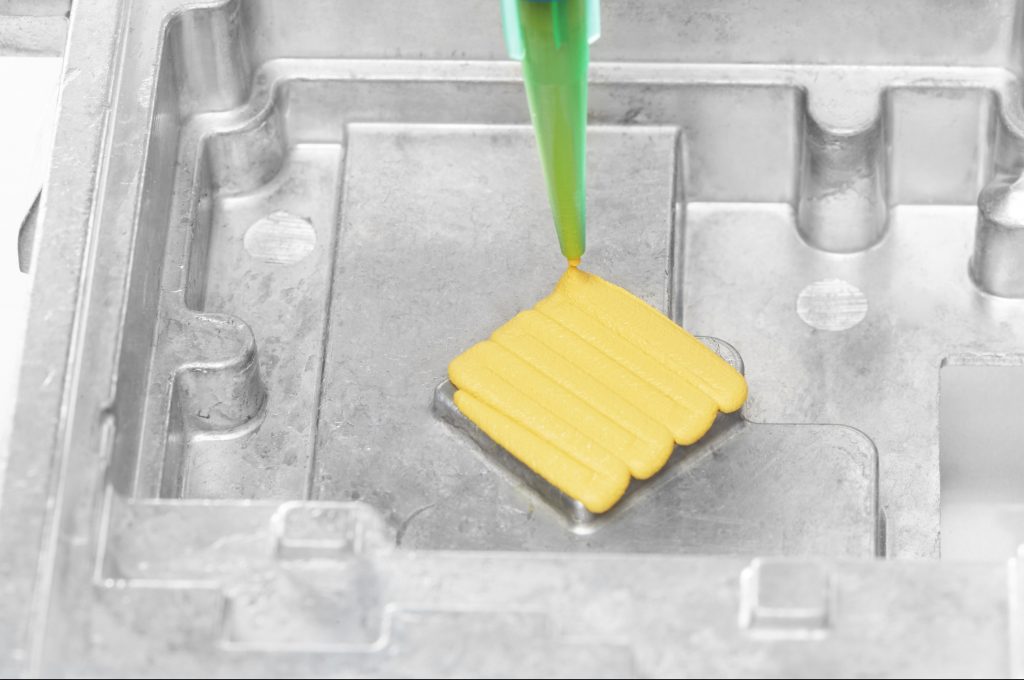

Simplify gasketing with volumetric dosing

In order to ensure that your final product is watertight, it is essential to make a seal.

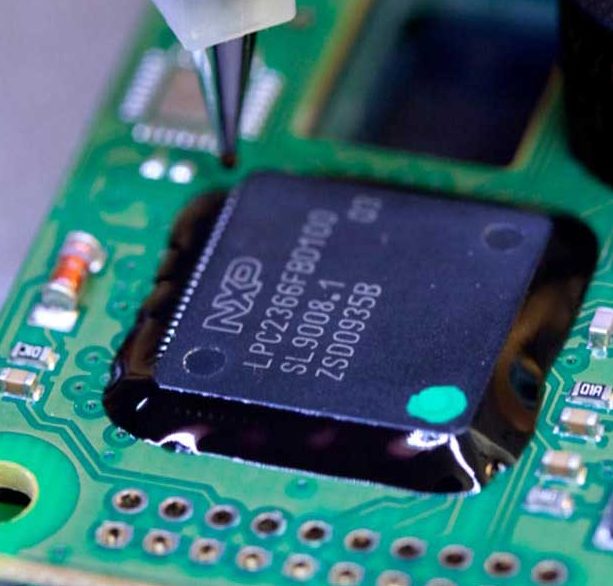

But this practice complicates your production cycle because of the long drying time?

A second problem that regularly arises is that of controlling the geometry of the bead: are you unable to optimise it?