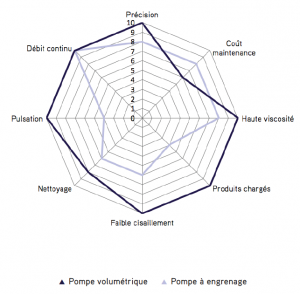

Comparator_Gear pump / Volumetric pump

Gear Pump VS Volumetric Pump

Gear Pump VS Volumetric Pump

1. ACCURACY.

This is particularly important when dosing so-called "sensitive" products such as hyaluronic acid, active ingredients, etc. or products with high added value.

Gear pump: 8/10

This pump system is not suitable for dispensing charged products, which reduces the precision of this pump.

Volumetric pump: 10/10

Volumetric pumps guarantee a very precise dosage to +/- 1% of the volumes thanks to the linearity between the rotor speed and the output quantity. There is also no drop at the end of the dosing with the re-suction system, which allows the same quantity of dosing to be repeated.

2. MAINTENANCE COSTS.

The maintenance costs of a material are to be included in the management of the production lines. However, it is important to estimate the reliability of the different materials and the frequency with which maintenance should take place.

Gear pump: 8/10

Low maintenance costs but high frequency. The system requires high responsiveness for cleaning and maintenance when indicated.

Volumetric pump: 6/10

Quite expensive maintenance but can be planned.

3. HIGH VISCOSITY.

In the cosmetics industry, many products that require dosing have a very high viscosity (mascaras, lipsticks, creams, etc.). It is therefore necessary to be able to dose them while maintaining their integrity.

Gear pump: 8/10

The dosing of high viscosity products is possible with the gear pump but in this case the system generates a high pressure leading to high shear rates, risking to denature the product

Volumetric pump: 10/10

Volumetric pumps are independent of viscosity. They are equipped with worm technology which guarantees a capacity to dose all types of liquid, viscous or even pasty products.

4. FILLED PRODUCTS.

Cosmetic or pharmaceutical products can sometimes contain fillers or solid particles. It is essential for professionals in the sector to guarantee the safe delivery and dosing of these products.

Gear pump: 4/10

This system is not suitable for loaded products, which can damage the pump or be damaged themselves (loads can be broken).

Volumetric pump: 10/10

The volumetric pumps are equipped with the technology of the endless screw, your loaded products, with or without solid particles will be dosed without suffering any degradation.

5. LOW SHEAR

In the packaging industry, low shear is required in order not to alter the viscosity of the product, its active ingredients and fillers in order to respect it to the maximum.

Gear pump: 6/10

A system that generates high pressure due to its design, the products are thus subjected to high shear rates.

Volumetric pump: 10/10

Equipped with worm technology, the

volumetric pump allows a constant flow of product, while preserving it from any shearing and avoiding any compression of the product.

6. CLEANING

Depending on the existing production lines, it may be essential to be able to change the products to be dosed on a regular basis. It is necessary to be able to clean the equipment on a regular basis without it being complicated to dismantle and reassemble.

Gear pump: 6/10

The cleaning time of this system is still important.

Volumetric pump: 8/10

Easy to clean, modular system and simple to dismantle and reassemble.

7. PULSATION

The guarantee of a pulsation-free deposit allows to optimize the repeatability of the dosage.

Gear pump: 4/10

Due to the design of the pump, the product is pressurised and causes a pulsation between the gears.

Volumetric pump: 10/10

The eccentric screw system creates a linear flow of material regardless of the viscosity of the product (even if this varies over time).

8. CONTINUOUS FLOW

It is necessary to have a continuous flow of material during filling.

Gear pump: 10/10

The pump's technology by means of a rotation system allows it to ensure a continuous flow rate, which is not, however, valid for filled products.

Volumetric pump: 10/10

The technology of the volumetric pumps without piston (eccentric screw) allows to guarantee dosages with unlimited continuous flow for liquid and viscous products, with or without fillers.

See our volumetric pumps

Gear Pump VS Volumetric Pump

Gear Pump VS Volumetric Pump

Gear Pump VS Volumetric Pump

Gear Pump VS Volumetric Pump