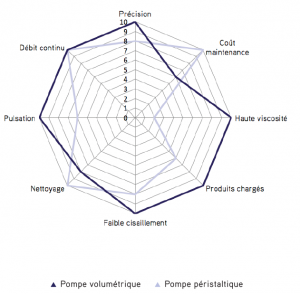

Comparator _ Peristaltic pump / Volumetric pump

Peristaltic pump VS Volumetric pump

Peristaltic pump VS Volumetric pump

1. ACCURACY.

This argument is particularly important when dosing so-called "sensitive" products such as hyaluronic acid, active ingredients, etc. or for products with high added value.

Peristaltic pump: 8/10

The peristaltic pump has a high dosing accuracy but this is only valid when dosing liquid products.

Volumetric pump: 10/10

The volumetric pumps guarantee a very accurate dosing to +/- 1% of the volumes thanks to the linearity between the rotor speed and the output quantity. There is also no drop at the end of the dosing with the re-suction system which allows the same quantity of dosing to be repeated.

2. MAINTENANCE COSTS.

The maintenance costs of a material are to be included in the management of the production lines. However, it is important to estimate the reliability of the different materials and the frequency with which maintenance must take place.

Peristaltic pump: 10/10

This pump requires little maintenance and is therefore low cost.

Volumetric pump: 6/10

Maintenance is quite expensive but can be planned.

3. HIGH VISCOSITY.

In the cosmetics industry, many products that require dosing have a very high viscosity (mascaras, lipsticks, creams, etc.). It is therefore necessary to be able to dose them while preserving their integrity.

Peristaltic pump: 2/10

This system depends on the viscosity. High viscosity products do not flow, even with high pressure. It cannot be dosed correctly without heating (which can denature the product).

Volumetric pump: 10/10

Volumetric pumps are independent of viscosity. They are equipped with worm technology which guarantees the ability to dose all types of liquid, viscous or even pasty products.

4. FILLED PRODUCTS.

Cosmetic or pharmaceutical products can sometimes contain fillers or solid particles. It is essential for professionals in the sector to guarantee the safe delivery and dosing of these products.

Peristaltic pump: 6/10

Filled products cannot be dosed due to the small diameter of the system. There is a risk that the charges will be denatured and broken.

Volumetric pump: 10/10

The volumetric pumps are equipped with the technology of the endless screw, your loaded products, with or without solid particles will be dosed without suffering any degradation.

5. LOW SHEAR

In the packaging industry, low shear is required in order not to alter the viscosity of the product, its active ingredients and fillers in order to respect it as much as possible.

Peristaltic pump: 8/10

Low shear for liquid or low viscosity products. However, high shear when the viscosity of the product increases.

Volumetric pump: 10/10

The

volumetric pump with screw technology allows a constant flow of product, while preserving it from any shear and avoiding any compression of the product.

6. CLEANING

Depending on the existing production lines, it may be essential to be able to change the products to be dosed on a regular basis. It is necessary to be able to clean the equipment regularly without it being complicated to dismantle and reassemble.

Peristaltic pump: 10/10

No cleaning, some elements are disposable.

Volumetric pump: 8/10

Easy to clean, modular system and simple to dismantle and reassemble.

7. PULSATION

The guarantee of a pulsation-free deposit allows to optimize the repeatability of the dosage.

Peristaltic pump: 6/10

The pulsation is linked to the viscosity of the product: the higher it is, the more pressure must be exerted on the product and the greater the pulsation effect.

Volumetric pump: 10/10

The eccentric screw system allows to create a linear flow of material whatever the viscosity of the product (even if it varies over time).

8. CONTINUOUS FLOW

It is necessary to have a continuous flow of material during filling.

Peristaltic pump: 10/10

This system allows a continuous flow only when the product is liquid and not loaded.

Volumetric pump: 10/10

The technology of the volumetric pumps without piston (eccentric screw) allows to guarantee dosages with unlimited continuous flow for liquid and viscous products, with or without fillers.

See our volumetric pumps

Peristaltic pump VS Volumetric pump

Peristaltic pump VS Volumetric pump

Peristaltic pump VS Volumetric pump

Peristaltic pump VS Volumetric pump